Products

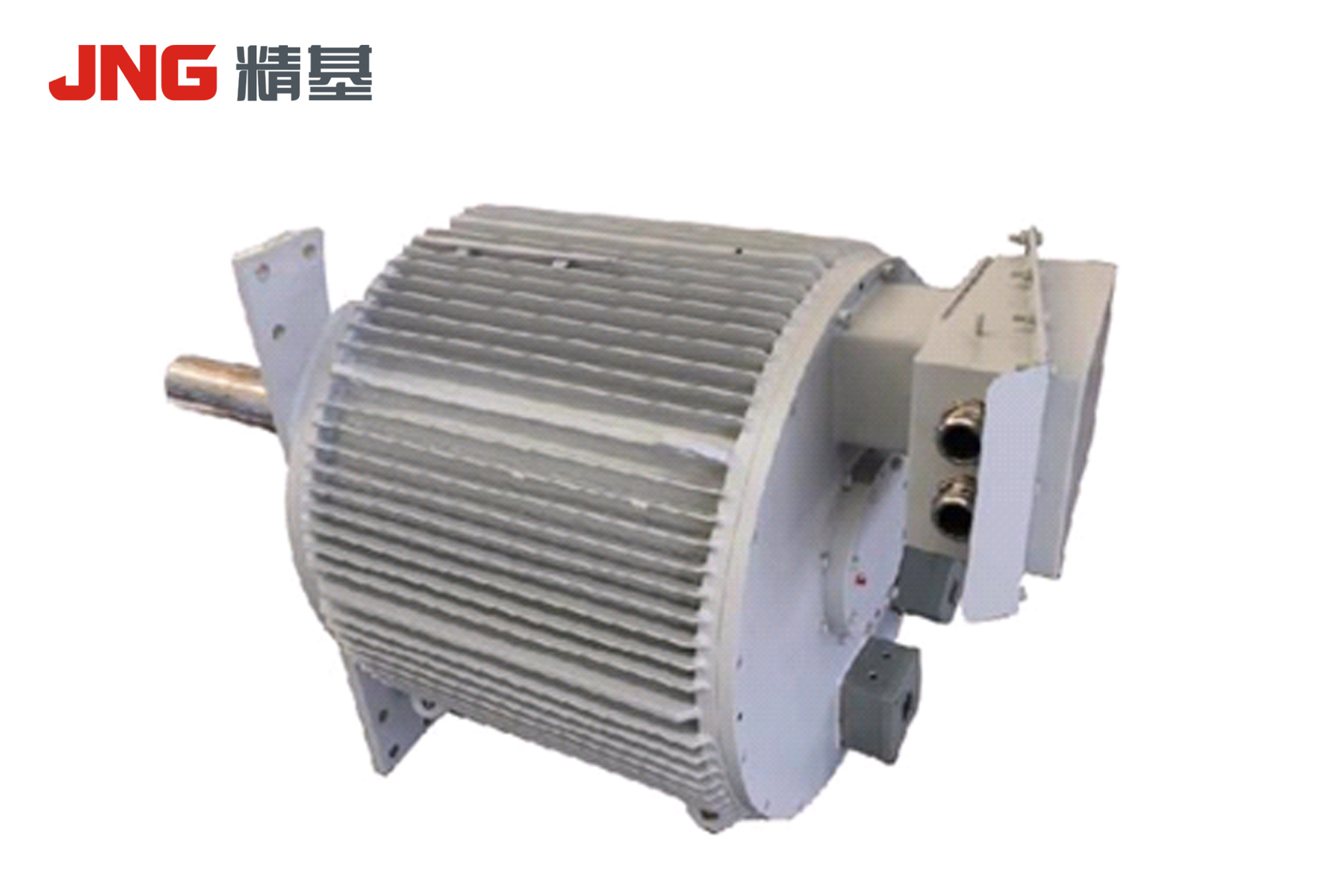

Motor for air-cooled island fan

Permanent magnet synchronous motor for screw compressor

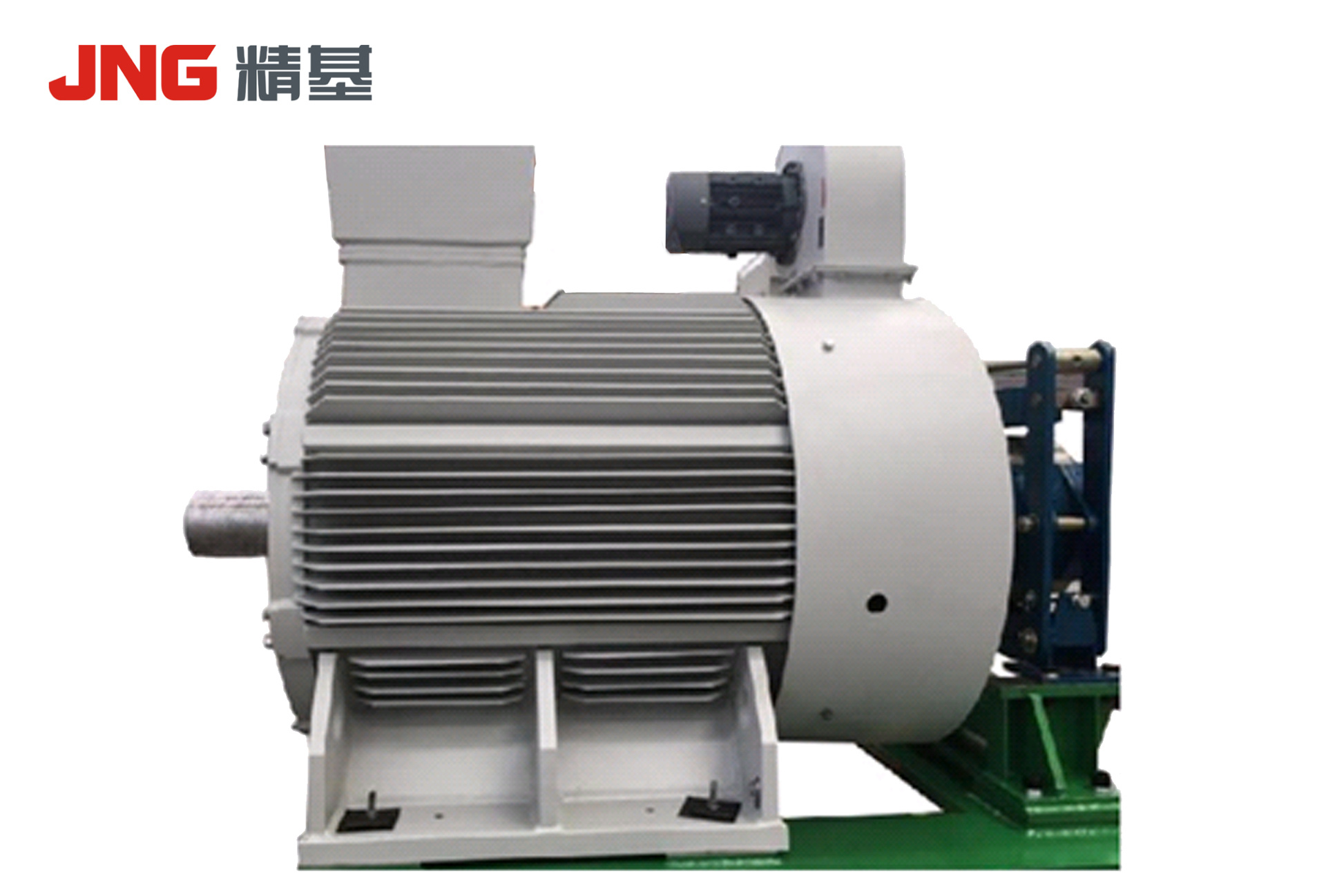

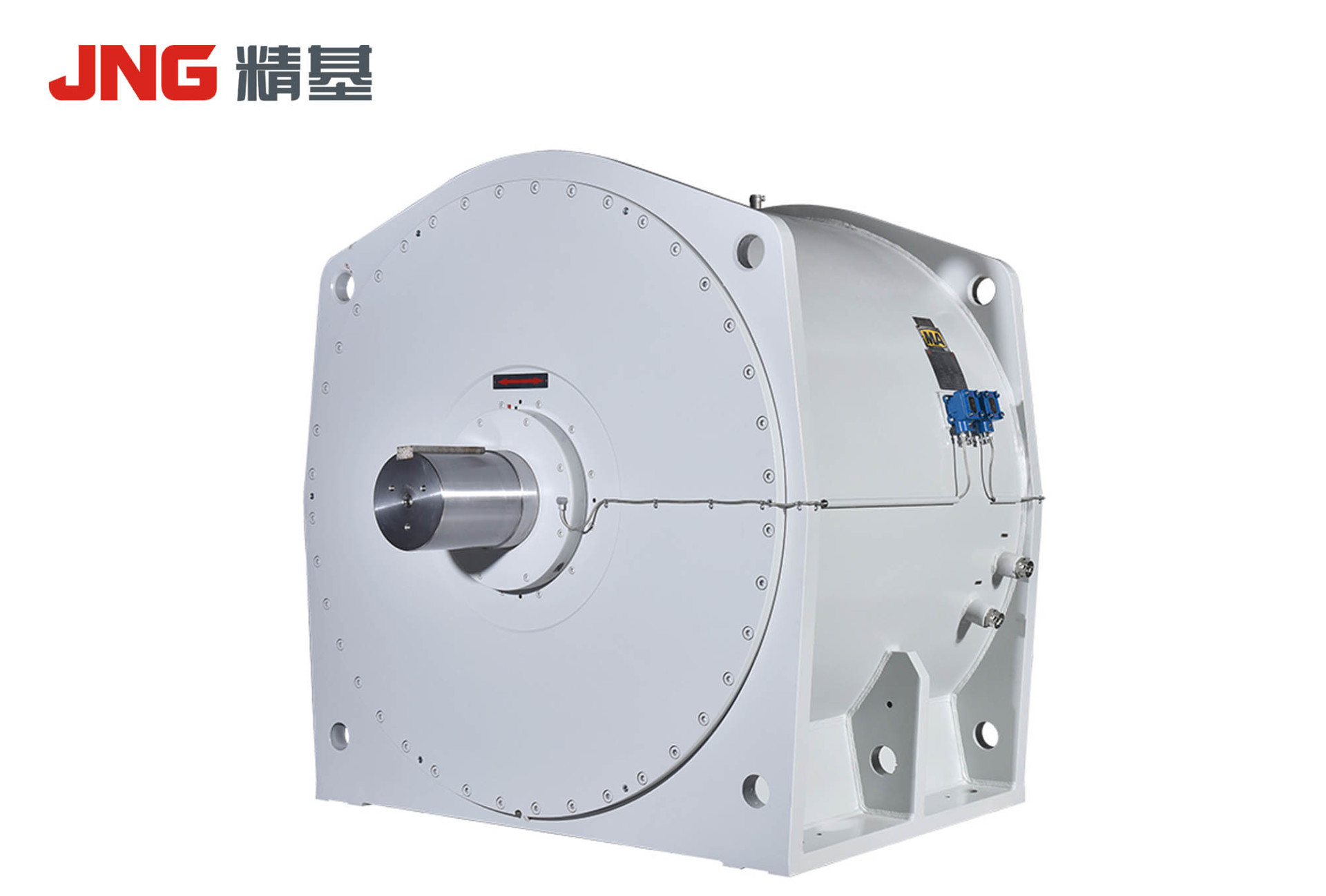

Three-phase permanent magnet synchronous motor for ceramic ball mill

Three-phase permanent magnet synchronous motor for cement mill

Three-phase permanent magnet synchronous motor for reciprocating compressor

Three-phase permanent magnet synchronous motor for belt conveyor

GX series basic type permanent magnet coupler

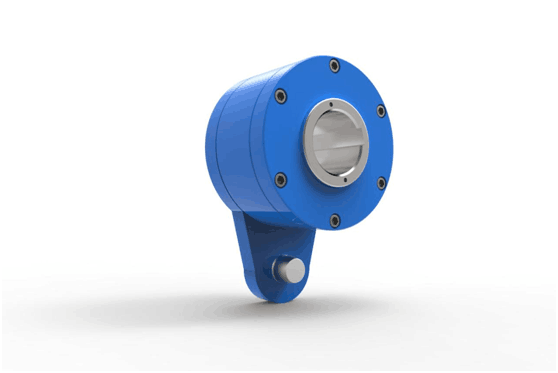

NF high speed non-contact-type backstop

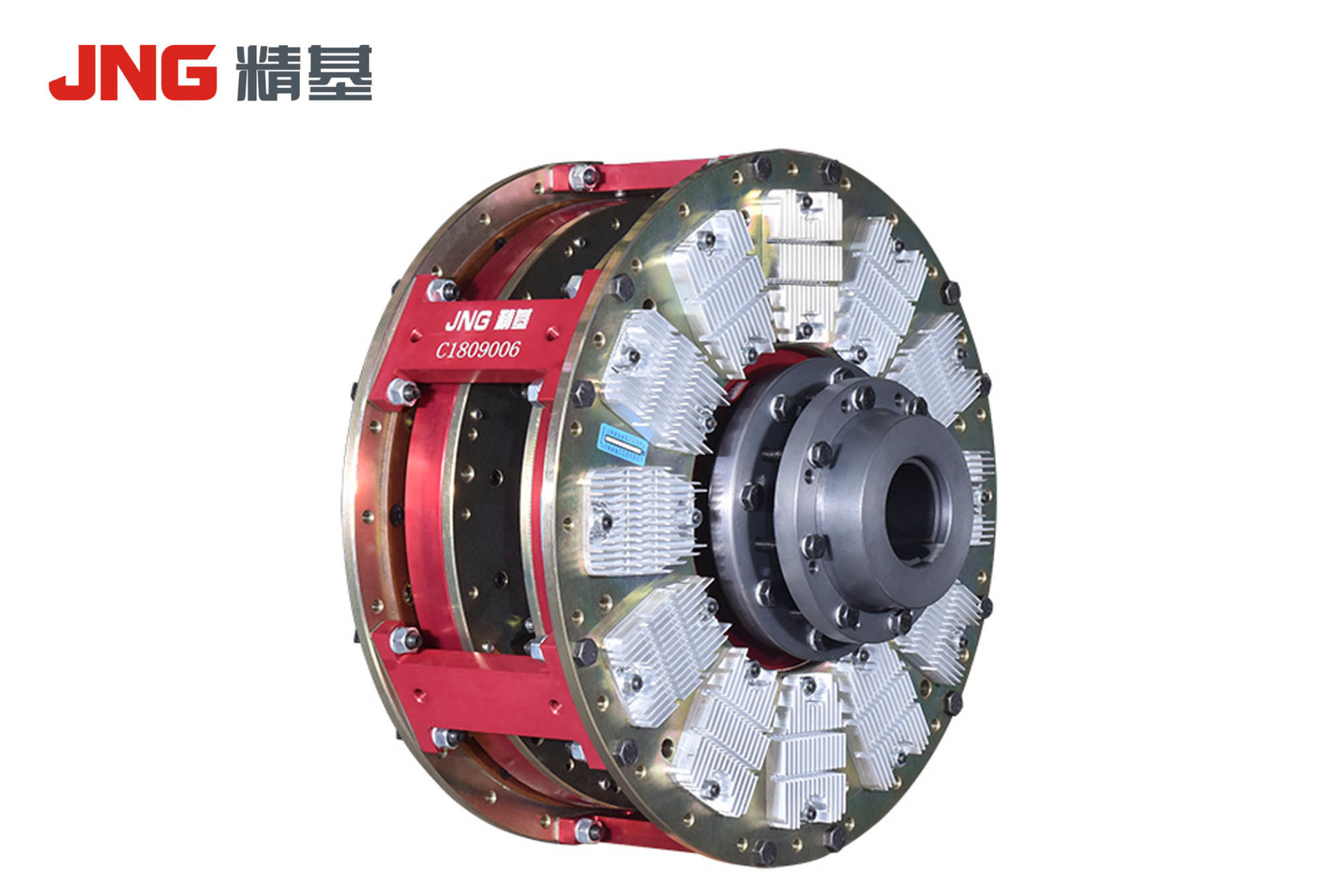

MTC series constant permanent magnet coupler

Explosive-proof and intrinsic safety type programmable control box KXJ127 for mines